- Solutions

- Total Valve Solutions

Valve Actuation and Automation Solutions

DNOW Total Valve Solutions (TVS) offers customized valve actuation, modification, and repair solutions.

DNOW Total Valve Solutions (TVS) is your total valve care solutions partner. Our three core capabilities—actuation, modification and repair—allow us to provide you with a full range of valve services. With service and sales offices from North America to UAE, we can serve you in gas transmission, upstream, midstream, industrial, mining and municipal industries. We have the personnel and resources to fulfill your every valve automation need.

Your Partner for Custom Valve Actuation and Automation Services

DNOW Total Valve Solutions (TVS) is your partner for custom valve actuated and automated services. With our extensive expertise and experience, we excel in providing top-notch solutions tailored to meet your specific requirements. Our vast inventory of valves, actuators and related components ensures we have the right tools for any project.

Our in-house solutions and field services guarantee that we can handle every aspect of your valve needs. Our dedicated team of professionals is committed to supporting you in any way possible. Whether you need assistance with system design, product selection or on-site installation, we are here to help.

Contact us today and discover how our unrivaled expertise and comprehensive services can benefit you. Trust DNOW Total Valve Solutions for all your valve needs.

TVS offers a combination of 3 core capabilities

Valve actuation services

Our actuation specialists are some of the most knowledgeable in the industry. We offer electric, pneumatic, direct gas and hydraulic actuators. We can also customize an automated system to fit your needs. We are here to help you find a modest, efficient, and economical actuation solution that meets your requirements.

Valve modification services

We can handle many modifications, from simple end connection alterations to more complete projects like a pup and stem extensions. Our machine shop and drafting department are well-equipped and staffed with experienced professionals, to take on any project you need.

Valve repair services

Here at DNOW Total Valve Solutions, we understand the importance of reliable repair and service. We offer complete in-shop repair and maintenance services and 24/7 field service capabilities with fully equipped service trucks. Our service technicians are highly skilled and have years of experience in valve repair and maintenance.

If you're in the market for a new actuator, DNOW is the place to be. We carry a wide range of actuators to help you get the job done, whether you need power, precision or speed. We also have a variety of options to choose from, including pneumatic, electric and hydraulic actuators. So whatever your needs may be, we have the actuator for you. Contact us today to learn more about our actuators and how we can help you get your machinery up and running again.

What if you could have an actuator that was custom built to fit your specific needs? At DNOW Total Valve Solutions, we can do just that. We have a wide range of actuators that can be customized to fit your needs. We have the experience and expertise to help you find the perfect actuator for your application. Contact us today to learn more about our custom-built actuators.

This valve has an actuator that is mounted on the truck and ready for delivery to the job site. The actuator is a pneumatic device that uses pressurized air to control the movement of the valve.

If you are in need of a quality actuator inspection, your local DNOW TVS store is the perfect place to go. We have a team of experienced professionals who know how to properly examine actuators to ensure they are in good condition. We also offer repair and replacement services if needed. Contact us today to schedule a consultation.

Our DNOW Total Valve Solutions technician is pressure testing valve assemblies on the production line. This is critical to ensure the valves function properly and do not leak when the pipeline is pressurized.

DNOW Total Valve Solutions specializes in the assembly of actuators and valves. Our team has the knowledge and experience to help you find the right product for your application, no matter the size of the valve.

Are you looking for a custom-sized actuator or valve? Look no further than DNOW TVS. We can assemble any size of actuator and valve to meet your specific needs. Plus, we have a wide selection of actuators and valves to choose from, so you're sure to find the perfect fit for your application. Contact us today to learn more about our custom-sized actuators and valves.

When it comes to your valve and actuators, you want to ensure they are working properly. That is where DNOW TVS technicians come in. We have the experience and expertise to ensure your valves are up and running. We use the latest technology and equipment to get the job done right, and we back our work with a 100% satisfaction guarantee. Contact us today to learn more about our valve services, or visit our website to learn more about our company.

The actuators are now fully tested by our DNOW Total Valve Solutions technicians and are available for shipping. They will be promptly delivered to our customer's job site. The actuators are available in a variety of sizes and with a number of different options, so they can fit each of the customer's specific needs.

Our DNOW field technicians can install, repair, and maintain your valves and actuators. We have the experience and knowledge to help you with your repair needs. Our team is dedicated to providing you with the best possible service. We understand the importance of timely repairs, so we work quickly to get your equipment back up and running.

If you are looking for reliable and affordable basic end connection modification DNOW Total Valve Solutions is the perfect service provider for you. Our team of experts are able to complete a wide range of modifications quickly and efficiently, ensuring that you are able to get your equipment up and running as soon as possible. Contact us today to find out more about our services or to receive a free quote.

DNOW offers a wide range of products to meet your specific application requirements. Our actuators and valves are designed and manufactured to the highest quality standards, and we can provide expert advice on selecting the right products for your needs. If you need help selecting the best actuators and valves for your application, please contact us and we will be happy to help.

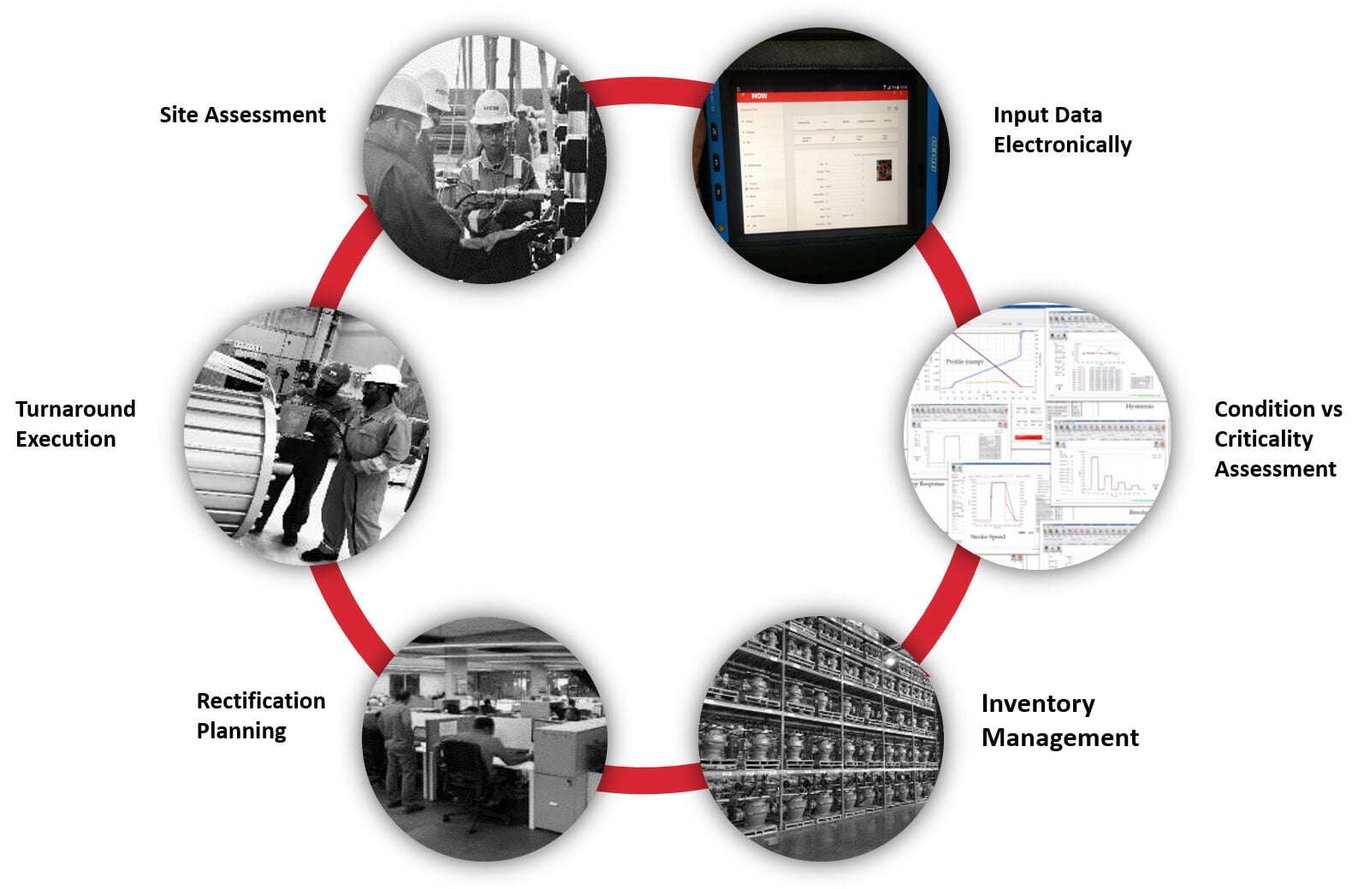

We help customers manage their valve assets

across the total life cycle

We are a leading stocking distributor of valves and related services to industries worldwide.

Our valve solutions are well equipped to meet the specific needs of each customer and application.

In-house solutions

- Installation or replacement of actuation packages

- Calibration of valves, actuators, and controls

- Hydrostatic and leakage testing

- Valve and actuator repair and reconditioning

- Changing valve trim and seats

- Providing sizing criteria, control logics, documentation, drawings, and functional testing

- Actuation package design

- CAD drafting

- “Outline” and “as built” dimension drawings

- Control schematics

- Wiring diagrams

- Custom control panel design

- Custom mounting kits and lock-outs

Field solutions

- Repair

- Replacement

- Commissioning

- Installation or replacement of automation packages

- Recalibration

- Site surveys

Valve reconditioning services

DNOW's rigorous reconditioning and recertification process restores valves to like-new conditions. We ensure that they meet the exact specifications and performance as new valves. Our dedication to meeting material specifications and performance standards enables us to provide you with mechanically sound valves.

Services include:

- Complete disassembly and breakdown down of valve and components

- A thorough inspection of all parts to ensure conformance with ASME, ANSI, and ISA standards

- Replacement of non-conforming parts

- Reassembly

- Complete pressure testing of the valve assembly (hydrostatic, seat, and performance)

According to a quality checklist, every step is tightly controlled to ensure that the valve conforms to all required regulatory standards. It also helps identify any failures or underperformance so that they can be addressed. A report is generated after each repair to help track any issues and ensure proper valve operation.

Valve service capabilities

- Site Survey

- Online Leak Detection

- Routine Maintenance

- Condition Monitoring

- Shutdown Repair & Testing Containers

- Commissioning

- Valve & Flange Management

- Leak Testing

- On site Flange Machining

- RFID /QR Code Tagging

- Control Valve Diagnostics

- High Pressure Hydrostatic & Pneumatic Testing

- OEM trained technicians

- Strip down & Inspection

- PMI Testing

- Recommendation for repair/upgrade

- Failure Analysis

- OEM parts stocking

- Machining & Welding

- Flange End Modification

- Valve & Actuator Integration

- Actuator Compatibility Assessment

- Valve Torque Measurement

- Mounting adaptor design & manufacture

- Control panel design & manufacture

- OEM trained Engineers

- Wide ranging Industry Experience

- Failure Analysis

- Criticality Assessment

- Project management

- Drafting and FE Modelling

- Datasheet Review

- Database Creation and Maintenance

- Engineering Upgrades

- Valves / Actuators / Instrumentation & Spares

- Consignment Solutions

- Identify and value assets

- Rationalization of Inventory

- Track and dispose assets

- ↓ Inventory investment

- ↑ Inventory availability

- Work order management

- Long Term Preservation & Maintenance

- Recertification & testing

- PMI Testing

Optimize Flow Control with DNOW's Advanced Actuated Valves and Automation Solutions

Elevate your flow control processes and boost productivity with DNOW's cutting-edge actuated valve products and services. Our extensive inventory includes customizable valve actuators, ensuring precise and efficient flow control tailored to your system's requirements. Our field technicians provide actuator field services, engineering services and in-house service and testing.

Why DNOW? Because we're committed to our customers

When you service your equipment with DNOW, you're ensuring that your operation stays up and running smoothly. Our comprehensive inventory of valves and actuators, as well as our knowledgeable service engineers, make us the ideal partner for keeping your business running. Here are three reasons why you should partner with DNOW:

-

Our actuation specialists are some of the most knowledgeable in the industry and we take great pride in our offerings from electric and pneumatic to direct gas and hydraulic.

-

Our modifications capabilities are very comprehensive with a complete in-house machine shop and a fully staffed drafting department capable of both 2D and 3D design, Total Valve Solutions has the expertise for almost anything from basic end connection alteration to the full pup and STEM extension.

-

Another place where total valve solutions really stand apart is with our repair and service department. Not only do we offer full-in shop repair and maintenance services, but we also have full 24/7 field service capabilities including fully equipped service trucks.