- Products & Services

- PVF

- Valves

- Franklin Valve

Franklin Valve

Double Block and Bleed Plug Valves

DNOW is an authorized distributor of Franklin Valve products, proudly manufactured and tested in Houston, Texas, with parts sourced globally. Franklin's DuraSeal™ DBB valves are in stock at DNOW and available for quick delivery for your MRO needs or your next project, including these critical applications where double block and bleed valves are ideal:

- Biofuels product isolation

- Multi-product manifolds

- Prover loops

- Custody transfer units

- Terminals

- Tank farm & oil depots

- Aviation fueling systems

- Offshore platforms

- Blending units

*Please note: You need a DNOW eCommerce account to view our online catalog. Don't have one? Register easily on our sign-in page or click here to learn more about our online store.

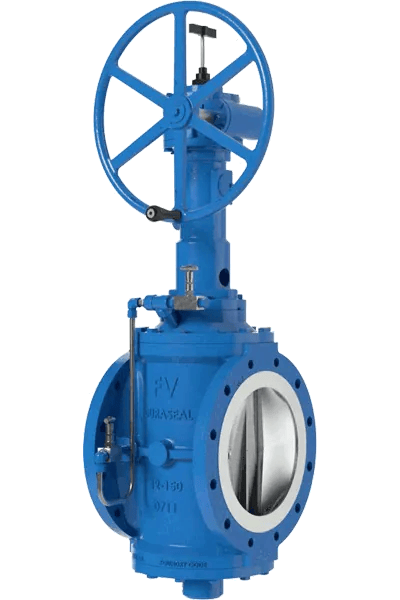

D700 Series DuraSeal™ DBB Plug Valves

Franklin Valve's DuraSeal series of double block and bleed plug valves incorporates a superior slip design, more durable body and a more reliable stem seal to improve integrity, performance and longevity. These valves are available in reduced port and full bore options, certified to ISO 9001, API 6D and API 6FA fire safe.

- 2 in. – 36 in.

- ANSI Class 150, 300, 600, 900

- Elastomer seal materials: Viton GF, Viton GFLT, Viton ETP, Kalrez®

- Body materials: A216 WCB, A216 WCC, A352 LCC

- Stem/Plug materials: A216 WCB, A216 WCC, A350 LF2, A352 LCC, all with 2-3 mils of ENP

- Standard temperature ratings: -20°F to 400°F (-28.9°C to 204.4°C)

- Low-temp ratings: -50°F to 400°F (-45.6°C to 204.4°C)

- Manual & electric operation

- Certified to API 6D, API 6FA, PED, ISO 15848-1 (optional)

Full information on flow, torque and actuator adaption is available in the following documents:

- Flow and torque data: PUB-005-EN

- Actuator adaption: SK-0014

| Model | Size | Pressure Class | Tapped Bleeder Hole | Bottom Plate Drain Hole |

|---|---|---|---|---|

| D711 | 2 in. | ANSI 150 | 3/8 in. NPT | 1/2 in. NPT |

| D711 | 3 in. | ANSI 150 | 3/8 in. NPT | 1/2 in. NPT |

| D711 | 4 in. | ANSI 150 | 1/2 in. NPT | 1/2 in. NPT |

| D711 | 6 in. | ANSI 150 | 1/2 in. NPT | 1/2 in. NPT |

| D711 | 8 in. | ANSI 150 | 1/2 in. NPT | 1/2 in. NPT |

| D711 | 10 in. | ANSI 150 | 1/2 in. NPT | 1 in. NPT |

| D711 | 12 in. | ANSI 150 | 1/2 in. NPT | 1 in. NPT |

| D711 | 14 in. | ANSI 150 | 1/2 in. NPT | 1 in. NPT |

| D711 | 16 in. | ANSI 150 | 1/2 in. NPT | 1 in. NPT |

| D711 | 18 in. | ANSI 150 | 1/2 in. NPT | 1 in. NPT |

| D711 | 20 in. | ANSI 150 | 1/2 in. NPT | 1 in. NPT |

| D711 | 24 in. | ANSI 150 | 1/2 in. NPT | 1 in. NPT |

| D711 | 30 in. | ANSI 150 | 1/2 in. NPT | 1 in. NPT |

| D711 | 36 in. | ANSI 150 | 1/2 in. NPT | 1 in. NPT |

| Model | Size | Pressure Class | Tapped Bleeder Hole | Bottom Plate Drain Hole |

|---|---|---|---|---|

| D721 | 2 in. | ANSI 300 | 3/8 in. NPT | 1/2 in. NPT |

| D721 | 3 in. | ANSI 300 | 3/8 in. NPT | 1/2 in. NPT |

| D721 | 4 in. | ANSI 300 | 1/2 in. NPT | 1/2 in. NPT |

| D721 | 6 in. | ANSI 300 | 1/2 in. NPT | 1/2 in. NPT |

| D721 | 8 in. | ANSI 300 | 1/2 in. NPT | 1/2 in. NPT |

| D721 | 10 in. | ANSI 300 | 1/2 in. NPT | 1/2 in. NPT |

| D721 | 12 in. | ANSI 300 | 1/2 in. NPT | 1 in. NPT |

| D721 | 14 in. | ANSI 300 | 1/2 in. NPT | 1 in. NPT |

| D721 | 16 in. | ANSI 300 | 1/2 in. NPT | 1 in. NPT |

| D721 | 18 in. | ANSI 300 | 1/2 in. NPT | 1 in. NPT |

| D721 | 20 in. | ANSI 300 | 1/2 in. NPT | 1 in. NPT |

| D721 | 24 in. | ANSI 300 | 1/2 in. NPT | 1 in. NPT |

| Model | Size | Pressure Class | Tapped Bleeder Hole | Bottom Plate Drain Hole |

|---|---|---|---|---|

| D741 | 2 in. | ANSI 600 | 1/2 in. NPT | 1/2 in. NPT |

| D741 | 3 in. | ANSI 600 | 1/2 in. NPT | 1/2 in. NPT |

| D741 | 4 in. | ANSI 600 | 1/2 in. NPT | 1/2 in. NPT |

| D741 | 6 in. | ANSI 600 | 1/2 in. NPT | 1/2 in. NPT |

| D741 | 8 in. | ANSI 600 | 1/2 in. NPT | 1/2 in. NPT |

| D741 | 10 in. | ANSI 600 | 1/2 in. NPT | 1 in. NPT |

| D741 | 12 in. | ANSI 600 | 1/2 in. NPT | 1 in. NPT |

| D741 | 14 in. | ANSI 600 | 1/2 in. NPT | 1 in. NPT |

| D741 | 16 in. | ANSI 600 | 1/2 in. NPT | 1 in. NPT |

| D741 | 18 in. | ANSI 600 | 1/2 in. NPT | 1 in. NPT |

| D741 | 20 in. | ANSI 600 | 1/2 in. NPT | 1 in. NPT |

| Model | Size | Pressure Class | Tapped Bleeder Hole | Bottom Plate Drain Hole |

|---|---|---|---|---|

| D751 | 2 in. | ANSI 900 | 1/2 in. NPT | 1/2 in. NPT |

| D751 | 3 in. | ANSI 900 | 1/2 in. NPT | 1/2 in. NPT |

| D751 | 4 in. | ANSI 900 | 1/2 in. NPT | 1/2 in. NPT |

| D751 | 6 in. | ANSI 900 | 1/2 in. NPT | 1/2 in. NPT |

| D751 | 8 in. | ANSI 900 | 1/2 in. NPT | 1/2 in. NPT |

| D751 | 10 in. | ANSI 900 | 1/2 in. NPT | 1 in. NPT |

More Franklin Valve Products from DNOW

In addition to the highlighted products above, DNOW has a full line of high-quality, innovative valve designs from Franklin Valve. These products are ideal for a variety of applications in the oil and gas industry, with proven high performance and easy service.

DuraSeal™ 4-Way Diverter Valves

Franklin Valve’s 4-way diverter valve design incorporates proven performance features and characteristics like ASME B16.34, multi-turn actuation, in-line maintenance and automatic pressure gauges.

- 2 in. – 16 in. (DN50 – DN400)

- ANSI Class 150, 300, 600

- Elastomer seal materials: Viton GF, Viton GFLT, Viton ETP, Kalrez®

- Body materials: A216 WCB, A216 WCC, A352 LCC

- Stem/Plug materials: A216 WCB, A216 WCC, A350 LF2, A352 LCC, all with 2-3 mils of ENP

- Standard temperature ratings: -20°F to 400°F (-28.9°C to 204.4°C)

- Low-temp ratings: -50°F to 400°F (-45.6°C to 204.4°C)

- Manual & electric operation

- Certified to PED (2 in. – 12 in.)

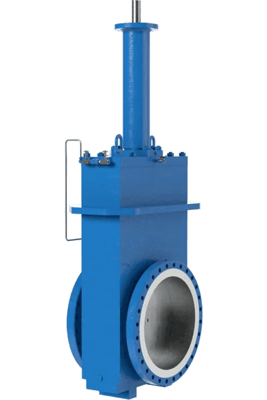

DuraGate™ Symmetrical Expanding Gate Valves

Franklin Valve’s new patented design symmetrical expanding gate is the first truly bidirectional flow S.E.G. for extended service in demanding sectors, solving many inherent issues with current industry offerings.

- 12 in. – 36 in.

- ANSI Class 150, 300

- Elastomer seal materials: Viton GF, Viton GFLT, Viton ETP, Kalrez®

- Body materials: 516-70/A350 LF2 ENP

- Stem material: 17-4 PH

- Standard temperature ratings: -20°F to 400°F (-28.9°C to 204.4°C)

- Low-temp ratings: -50°F to 400°F (-45.6°C to 204.4°C)

- Manual & electric operation

- Certified to API 6D, API 6FA fire safe, ISO 15848-1

About Franklin Valve

Franklin Valve is a privately held valve manufacturer in Houston, Texas. Franklin places the highest value on product quality and customer service and is committed to positioning the DuraSeal™ double block and bleed plug valve as the premier DBB valve on the market. You can always rely on Franklin’s commitment to manufacture the valves that meet your challenging requirements.

Let Franklin Valve products be a part of your next project. www.franklinvalve.com